Imagine a robust shield for your metals and materials—one that stands strong against the elements and everyday wear. Enter powder coating, a cutting-edge surface treatment designed to protect and enhance. This innovative process involves electrostatically applying a free-flowing powder that bonds to surfaces and is then cured using heat or UV light. While it can be applied to a variety of materials, its primary partners are steel, and aluminum.

Why Choose Powder Coating?

Metals, even those branded as stainless, are susceptible to corrosion under certain conditions. A protective layer of powder coating is the ideal solution, providing a resilient, corrosion-resistant barrier that can endure the rigours of everyday use.

What makes powder coating so appealing? Its durability! Available in a myriad of colours and textures, powder coating shines in demanding environments, such as industrial machinery and automotive parts.

But it’s not just metals that benefit. Carbon fibre, and even MDF (medium-density fibreboard) can all gain a protective layer against harmful UV rays and other environmental factors, enhancing their longevity and aesthetics.

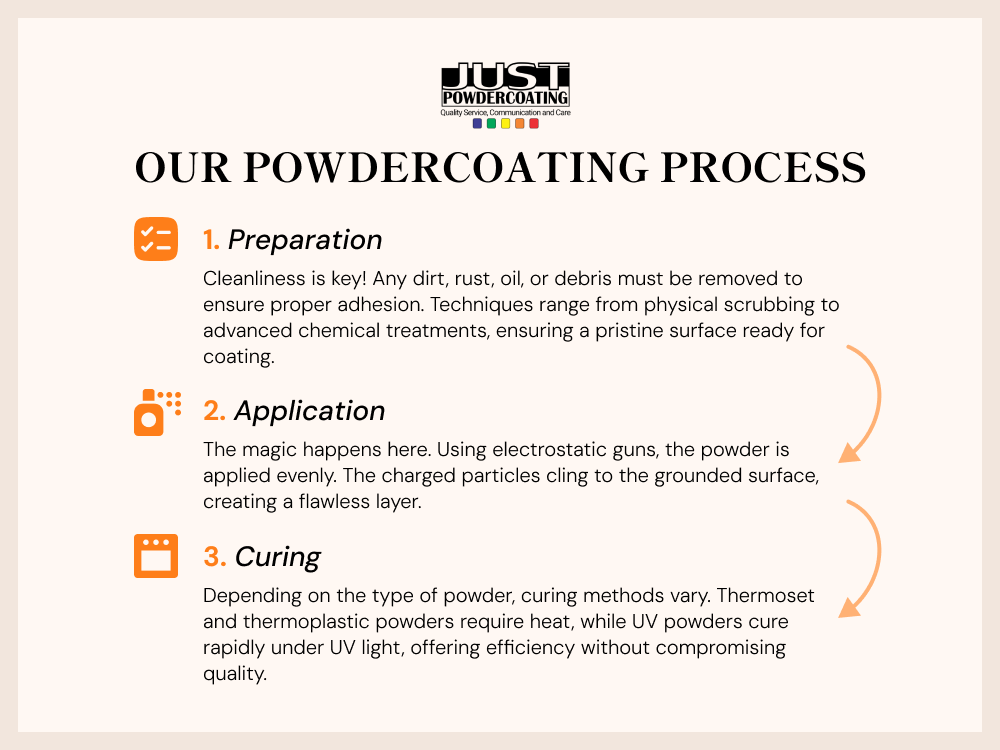

The Science Behind Powder Coating

Powder coating falls into three main categories: thermoset, thermoplastic, and UV curable. Each has unique characteristics, but they all share a common goal: to create a uniform, durable finish that protects against corrosion.

- Thermoset Coatings: Thermoset powders are the most popular choice due to their cost-effectiveness and ease of application. At Just Powdercoating, we specialise in using high-quality thermosetting coatings.

- Thermoplastic Coatings: Known for their flexibility and impact resistance, thermoplastic powders can be recycled after re-heating, making them a sustainable choice.

- UV Curable Coatings: This innovative option cures under UV light, allowing heat-sensitive materials like wood to be coated without damage. The process is not only faster but also reducing energy costs—an eco-friendly win!

The Advantages of Powder Coating

- Rust Resistance: Say goodbye to rust! Powder coating forms an impenetrable barrier, even on metals like brass and copper.

- Superior Durability: Harder than conventional paints, powder coatings withstand heavy use and extend the lifespan of your products.

- Exceptional Finish: Free from pinholes and blemishes, powder-coated surfaces are consistently smooth and visually appealing, regardless of orientation during application.

- Aesthetic Versatility: Available in an endless palette of colours and finishes, powder coating allows for stunning designs that merge strength with style.

- Eco- Friendly: With no volatile organic compounds (VOCs) and the ability to recycle overspray, powder coating is a cleaner, greener alternative to traditional paints.

- Quick Curing: The fast-curing times—especially with UV options—mean quicker turnaround and enhanced productivity.

Considerations and Challenges

While the benefits are numerous, there are a few limitations to consider. Heat curing restricts the application to heat-resistant materials, which means some polymers and composites are off the table. Additionally, achieving a perfect finish can be tricky with thin layers, as they may develop the “orange peel” effect. However, with expertise of a skilled powder coater, these challenges can easily navigate to ensure optimal results.

Lastly, the initial investment in powder coating equipment can be substantial compared to traditional painting methods. However, the long-term savings and benefits often outweigh this initial cost.

Conclusion

In the world of surface treatments, powder coating stands out as a powerhouse. Its robust protection, aesthetic versatility, and eco-friendly attributes make it a top choice for manufacturers and designers alike. Whether safeguarding metals against rust or providing a stunning finish for plastic parts, powder coating truly transforms surfaces and elevates products to new heights.

Contact us today to learn how our powder coating solutions can protect and enhance your products.